An Interview with Verly Widiantoro, Director of Engineering and Production at WIKA Beton

Verly Widiantoro, Director of Engineering and Production at WIKA Beton | Photo: WIKA Beton

Can you tell us about your organization and your current role?

PT Wijaya Karya Beton Tbk (WIKA Beton) was established as one of the subsidiaries of the state-owned enterprise PT Wijaya Karya (Persero) Tbk in 1997, with a vision to become a leading company in the Engineering-Production-Installation (EPI) field in the Southeast Asian concrete industry. To achieve this vision, WIKA Beton operates 14 factories, 1 mobile plant, 3 crushing plants, and 3 jetties spread across Indonesia, where the construction industry is experiencing significant growth. Currently, WIKA Beton also has 4 subsidiaries.

WIKA Beton is committed to sustainability with the triple bottom line principles: People, Planet, Profit. As one of the Board of Directors of WIKA Beton, I have the responsibility to set the direction of the company and control its operations to achieve the company’s vision and mission. Additionally, I lead the company’s initiatives to contribute to building a sustainable future. WIKA Beton continually innovates not only to be a market leader in the concrete industry but also with the belief that every action of the company should positively contribute to society and the environment.

What are your corporate sustainability commitments and goals?

As one of the players in the national concrete industry, WIKA Beton has been integrating sustainability into every aspects of its operations. We have taken several bold steps to reduce environmental impact in line with our commitment to sustainable development.

Firstly, we have adopted the use of more environmentally friendly materials. Currently, 60% of our total cement consumption can be classified as environmentally friendly cement. We plan to increase this to 80% next year and continue to increase it annually. We also utilize coal waste fly ash as a substitute for cement in concrete production, artificial coarse aggregate materials from factory waste, nickel slag, and Ground Granulated Blast Furnace Slag (GGBFS).

Secondly, we focus on developing ‘green concrete’ product innovations that are not only more environmentally friendly but also prioritizing quality standards. Examples include porous concrete, segmented infiltration well products, and geopolymer concrete.

Thirdly, our production process has implemented a zero-waste approach to the centrifugal precast-concrete compaction process. We have also introduced non-steam innovations in the production acceleration process. Furthermore, the energy for lighting in all our factories comes from solar cells.

What have been your most difficult challenges in achieving those goals?

Based on data from the Circularity Gap Report (2023), 40% of global greenhouse gas emissions come from construction activities, use, and demolition of buildings. As a producer whose main activities involve natural resources like natural stone and sand, we feel compelled to reduce the negative emissions impact. This effort naturally affects costs. We must brainstorm ways to continue production competitively while not exacerbating environmental damage.

What opportunities do you see to address those challenges?

We see the opportunity to develop environmental innovations, such as by using new environmentally friendly technologies. It’s also a chance to promote resource efficiency, which involves optimizing the use of raw materials and resources, adopting practices that reduce waste, and increasing recycling. Additionally, we have invested in solar cell installations and Solar Power Plants (PLTS). Investing in renewable energy not only reduces our carbon footprint but also lowers long-term energy costs.

Furthermore, we see significant opportunities in projects focused on sustainability, such as IKN projects and others. Another related issue is green concrete. We actively advocate for the use of green concrete to create a larger market demand for sustainable products. Our goal is to make the WIKA Beton brand known as an environmentally conscious company, both among the public and local or international investors.

Finally, we also consider collaboration with the government, society, and other stakeholders essential to shaping a sustainable business.

What are the ESG material (environmental, social, and governance) issues that your organization focuses on, and how do you integrate them into your corporate sustainability?

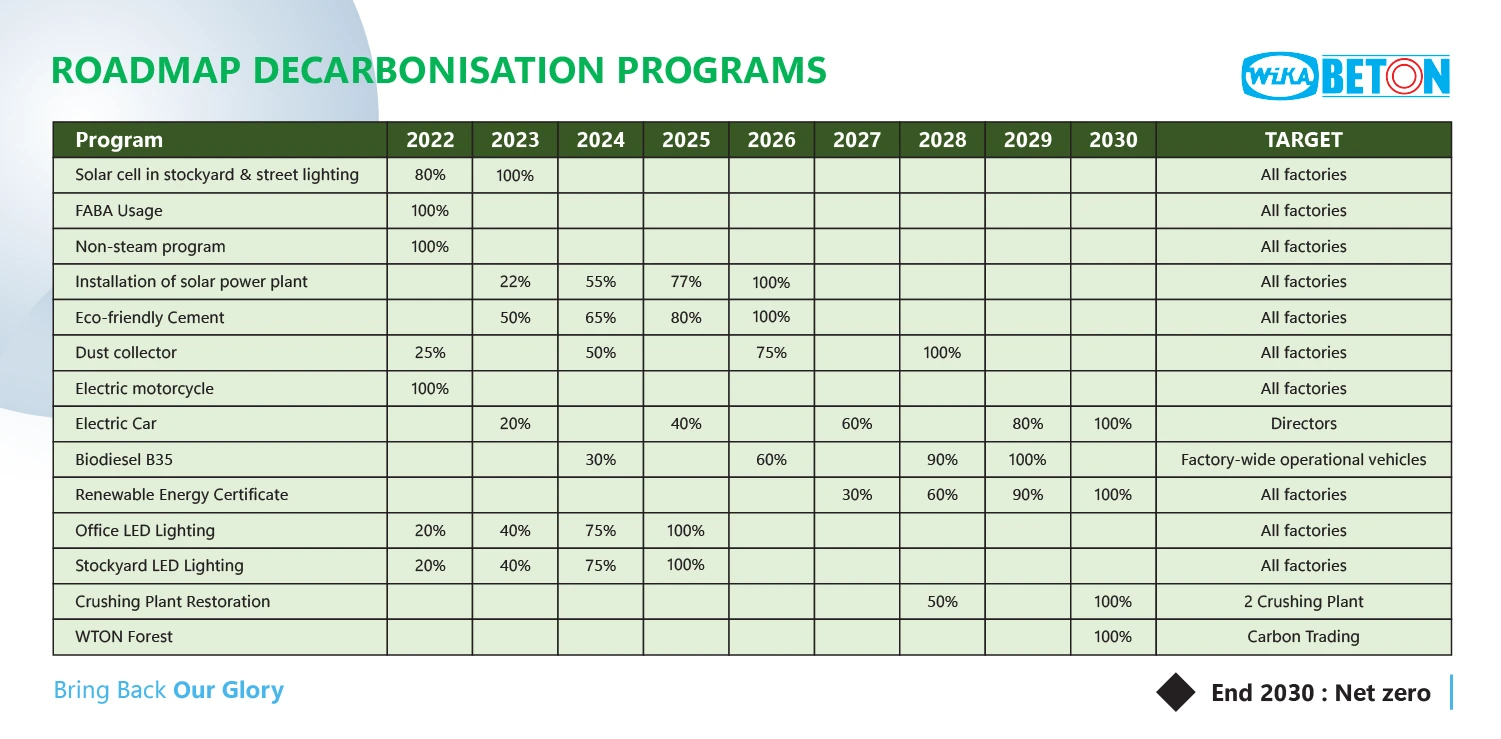

We implement a comprehensive approach to Environmental, Social, and Governance (ESG) issues, with our current primary focus on decarbonization and renewable energy. We don’t just comply with these principles; we’ve integrated them into the core of our business operations.

Image:

How do you communicate your corporate sustainability strategy and initiatives to internal and external stakeholders?

Transparency and accountability are crucial in communicating our sustainability strategy to stakeholders. We also aim to instill awareness of sustainability practices starting from our own employees. We ensure that all our successes and challenges are shared openly. This information is easily accessible on our website, social media, and in the sustainability report.

What were the most exciting initiatives and progress that you and your team have done in 2023?

In 2023, we took proactive steps to achieve our sustainability goals. We have implemented significant measures to reduce carbon footprint and execute decarbonization programs leading to net-zero by 2030.

What are the lessons you learned from your sustainability efforts in 2023?

The year 2023 highlighted the importance of resilience and strategic Corporate Social Responsibility (CSR). We learned that CSR is not just about doing good; it’s about aligning our CSR efforts with the goals and core values of our business, creating a symbiotic relationship between our business operations and our social and environmental responsibilities.

What are your plans for your sustainability efforts in 2024?

Our focus is on continuing to build sustainability efforts on the existing foundation. We plan to increase community engagement, further integrate sustainability into our business model, and uphold our commitment to innovation.

If you were to share advice you learned in your role that may be helpful to your peers and sustainability practitioners around the world, what would that be?

If I were to offer a piece of advice, it would be this:

“Sustainability is a continuous journey, not a final destination. It requires patience, dedication, and a commitment to ongoing learning and adaptation. We must do more than just conduct business; we must conduct business responsibly and sustainably.”

Editor: Nazalea Kusuma

Exploring Technological Advancement to Replace Animal Testing

Exploring Technological Advancement to Replace Animal Testing  Addressing Overconsumption for Transformational Changes

Addressing Overconsumption for Transformational Changes  Global Reform on Fisheries Subsidies Signals a Hopeful Shift Toward Ocean Sustainability

Global Reform on Fisheries Subsidies Signals a Hopeful Shift Toward Ocean Sustainability  A Major Cause of Changing Rainfall Patterns

A Major Cause of Changing Rainfall Patterns  Strengthening Disaster Risk Governance at Local Levels

Strengthening Disaster Risk Governance at Local Levels  Recognizing the Role of Local Communities in Biodiversity Conservation

Recognizing the Role of Local Communities in Biodiversity Conservation